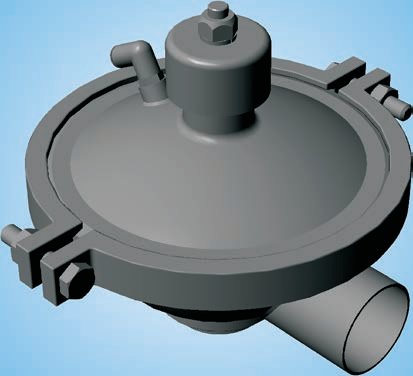

CPM VALVE

Reliable product for continuous operations.

• Designed for direct welding of the valve into sanitary piping system.

• Designed for smooth passage of the product with minimum pressure drop across the valve.

• Hygienic design suitable for Cleaning-In-Place (CIP)

• To maintain the back pressure at the inlet side of the valve.

• Typically applications are after separators, pasteurizers, heat exchangers to maintain back pressure.

IDMC Constant Pressure Modulating Valves are used in dairy, food, beverages and

pharmaceutical industry.

• To maintain a constant pressure in the process line at the inlet side of the valve.

Sizes : SMS 38 to SMS 76 (from pipe OD 1.5” to 4” suitable for ASTM A270)

• Product wetted steel parts : SS 316 L or SS 304

• Other steel parts : SS 304

• Product contact Gaskets/Seals : TEFLON coated food grade rubber

• Maximum product pressure : 10 Bar

• Maximum air pressure : 6 bar (Dry and moisture free air)

• Air connection : 6 mm diameter PU tube

• Temperature range : 2°C to 121°C

CPM valves are controlled by means of compressed air and operate without a transmitter in product line. If needed, a

pressure regulator and pressure gauge can be installed to control the compressed air for maintaining required back

pressure in the product line.

• A diaphragm / valve disc system reacts immediately to any alteration of the product pressure and changes position so

that the required pressure is maintained in the pipeline.

(Here Is The Product's Brochure Pdf File.)

Submit Inquiry